jawcrusherjawcrusherjawcrusher

2020-01-28T08:01:22+00:00

Retsch : 产品 : 粉碎设备 : 颚式粉碎仪

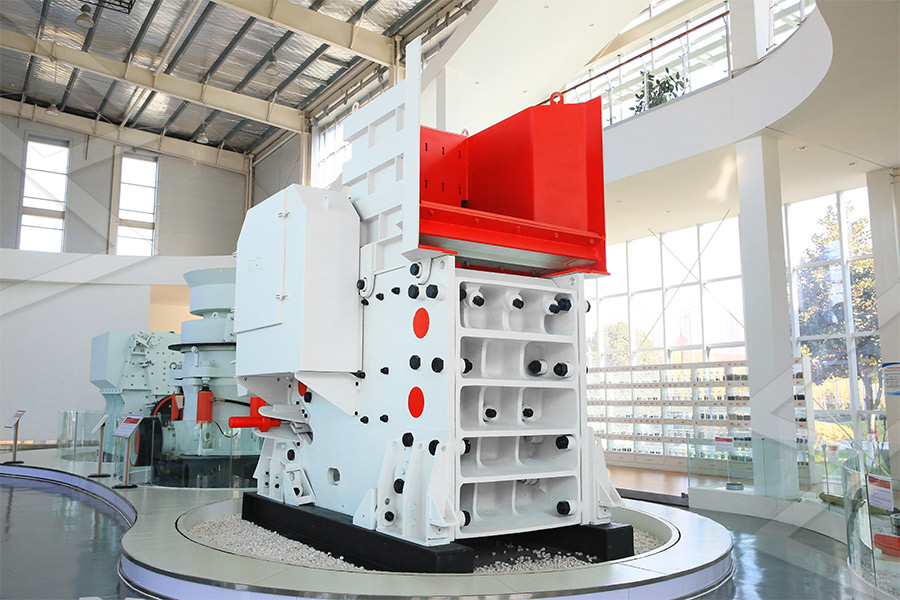

颚式研磨仪应用领域 A jaw crusher is always at the very front of the sample preparation chain, precrushing all hard and brittle materials The RETSCH jaw crusher range is PE Series Stone Jaw Crusher, jaw crusher, Jaw Crusher machine Introduction: The series of our Jaw crusher are 6 models which can meet most capacity requirements in primary Stone Crusher China Jaw Crusher, Crusher

Jaw Crusher, Jaw Crusher price, jaw crusher manufacturer

1 天前 Compared with traditional jaw crusher, JC series jaw crushers pays more attention on details in the process of design and manufacture It uses highstrength materials, 2024年1月19日 Jaw crusher is a trusted and reliable brand for its high quality and good manufacturing Jaw Crusher which is widely applied to Jaw Crusher, Jaw Crusher Machine, Rocks Jaw

Jaw Crusher SpringerLink

2023年6月21日 The movable jaw plate approaches the fixed jaw plate periodically to realize the functions of crushing, splitting, breaking, and impacting, thus to coarsely or Introduced in 1906, McLanahan’s Universal Jaw Crusher was one of the first modern era overhead eccentric Jaw Crushers On the overhead eccentric style Jaw Crusher, the McLanahan Jaw Crushers

Jaw crusher, Jaw crushing and screening plant All

jaw crusher BR380JG3 mobile Capacity: 50 t/h 240 t/h Motor power: 159 kW Opening height: 1,065 mm Ecofriendly performance moving to a new stage The operating weight of the BR380JG3 ranges from 33,500 to 2022年11月21日 Our solutions for the hardest jobs Fields of application and design characteristics They are used in mines and quarries as primary crushers to crush blasted Industrial Solutions Jaw crushers ThyssenKrupp

® C Series™ jaw crushers Proven reliability and

2021年7月16日 ® C Series™ jaw crushers have proven to be reliable and productive in thousands of mining, quarrying, recycling and industrial applications with up 2018年10月15日 10 One or twopiece jaws Large C Series™ jaw crushers (C110™ and bigger) were originally designed for use with a twopiece jaw die, while the smaller jaw ® C Series™ jaw parts

Jaw Crushers – MEKA

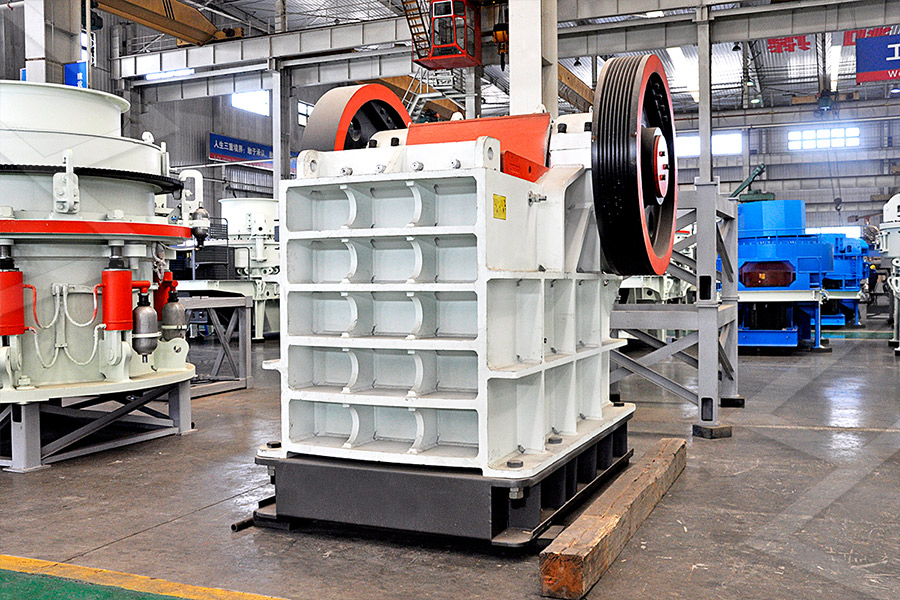

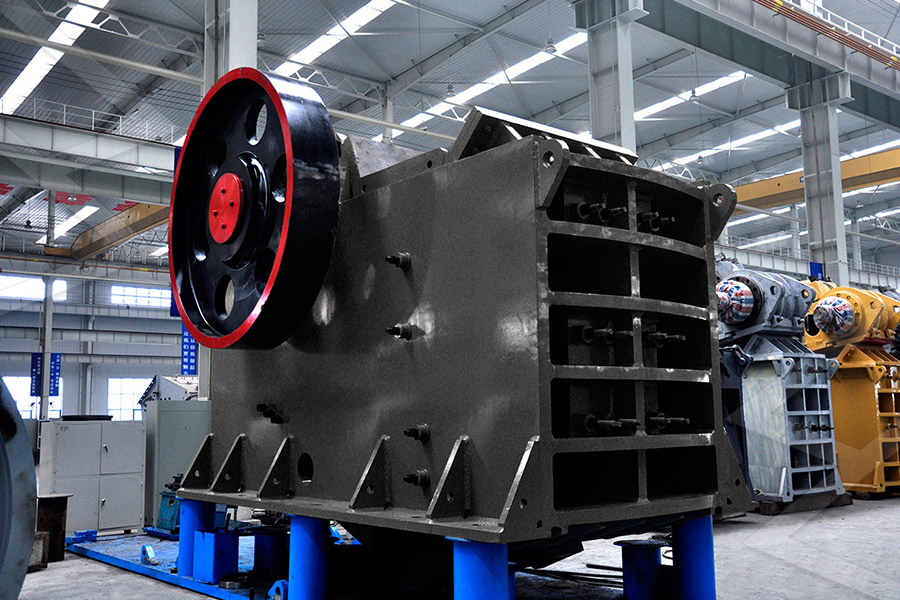

Jaw crushers reduce large rocks or ore by means of compression Mechanical pressure is applied using the crusher’s two jaws; one is fixed while the other makes an eccentric movement There are also primary Rose and English [9] determined the capacity of a jaw crusher by considering the time taken and the distance travelled by the particles between the two plates after being subjected to repeat crushing forces between the jaws Therefore, dry particles wedged between level A and level B (Figure 44) would leave the crusher at the next reverse movement of the jawJaw Crusher an overview ScienceDirect Topics

What Are Jaw Crushers and How Do They Work? Oreflow

2019年3月28日 In a doubletoggle jaw crusher, the moving crusher jaw is driven by the eccentric shaft that moves the front and rear toggles up and down Each shaft revolution causes the moving crusher jaw to close at the downstroke and open up during the upstroke The toggle is kept in place by springloaded tension rod2022年9月20日 This study reports on the design optimisation of the swinging jaw crusher plate Jaw crusher machines are used in the mining and construction industry for crushing rocks and mineral ores to the appropriate sizes for direct application or further processing During the crushing process, large and nonevenly distributed impact forces occur, Optimisation of the swinging jaw design for a single toggle

Jaw Crusher Heavy Duty Jaw Crusher Latest Price,

Roljack Asia Limited Contact Supplier Delhi Scientific Mild Steel Jaw Stone Crusher Manufacturer, Capacity: 300 KG To 500 Ton Per Hour ₹ 50,000 Delhi Scientific Contact Supplier Mild Steel 48"x36" (1200x950mm) Primary Jaw Crusher ₹ 65 Lakh Deepa Machinery Manufacturers Private Limited2020年2月14日 Jaw crusher mempunyai keunggulan struktur sederhana, kinerja stabil, perawatan mudah, menghasilkan partikel akhir dan rasio penghancuran tinggi Jadi jaw crusher merupakan salah satu mesin penghancuran paling penting dalam lini produksi penghancuran batu Secara umum mesin Crusher dapat digunakan untuk mengurangi JAW CRUSHER LinkedIn Indonesia

The Ultimate Guide to Replacing Toggle Plates in Jaw

2023年2月17日 Here are some best practices for maintaining toggle plates: Monitor the condition of the plates: Regularly inspect the toggle plates for signs of wear and tear, and replace them as needed Keep the jaw crusher clean: Clean the jaw crusher regularly to prevent dirt and debris from accumulating on the toggle platesA crusher is a machine designed to reduce the size of large rocks to smaller rocks , gravel , sand, or rock dust; this is essential for efficient transport of the product via conveyors etc Crushing is the first of many stages that lead to separation of the mineral (s) from the waste ( gangue) material Waste material can be discarded or Jaw Crusher Explained saVRee

Jaw Crushers high quality and reliability from RETSCH

Retsch Products Milling Jaw Crushers The RETSCH Jaw Crusher range is used for the rapid, powerful crushing and precrushing of mediumhard, hard, brittle and tough materials The variety of materials offered, their efficiency and safety make them ideal for sample preparation in laboratories and industrial plants Benchtop Unit2020年8月14日 The Discrete Element Method (DEM) is a numerical method that is able to simulate the mechanical behavior of bulk solids flow using spheres or polyhedral elements, offering a powerful tool for Minerals Free FullText DEM Simulation of

Jaw Crushers Price, 2024 Jaw Crushers Price Madein

The cost of a Jaw Crushers Price can vary widely depending on its size, capabilities, and complexity Most of the price of Jaw Crushers Price ranges from US $ 516 to $ per Set It's important to research and compare different models and features to find the best Jaw Crushers Price for your needs and budget Q2019年5月30日 Double Toggle—Blake Type or Overhead Pivot Movement Double toggle movement jaw crushers like the Blake style (named for the inventor of the first successful mechanical jaw crusher, Eli Whitney 5 Common Questions about Jaw Crushers Answered

Jaw Crusher Eastman Rock Crusher

Capacity 11120t/h Output Size 10350mm Jaw crusher is a compression style rock crusher, useful in crushing the mediumhard to very hard material into a smaller particle size at primary crushing stage in the crushing circuit Applications mining, quarry, construction waste recycling, aggregate making, etc MaterialsThere are two basic types of jaw crushers: single toggle and double toggle In the single toggle jaw crusher, an eccentric shaft is on the top of the crusher Shaft rotation causes, along with the toggle plate, a compressive action A double toggle crusher has two shafts and two toggle plates The first shaft is a pivoting shaft on the top of Crushers All crusher types for your reduction needs

What Is a Jaw Crusher? Here's How It Works Cutting

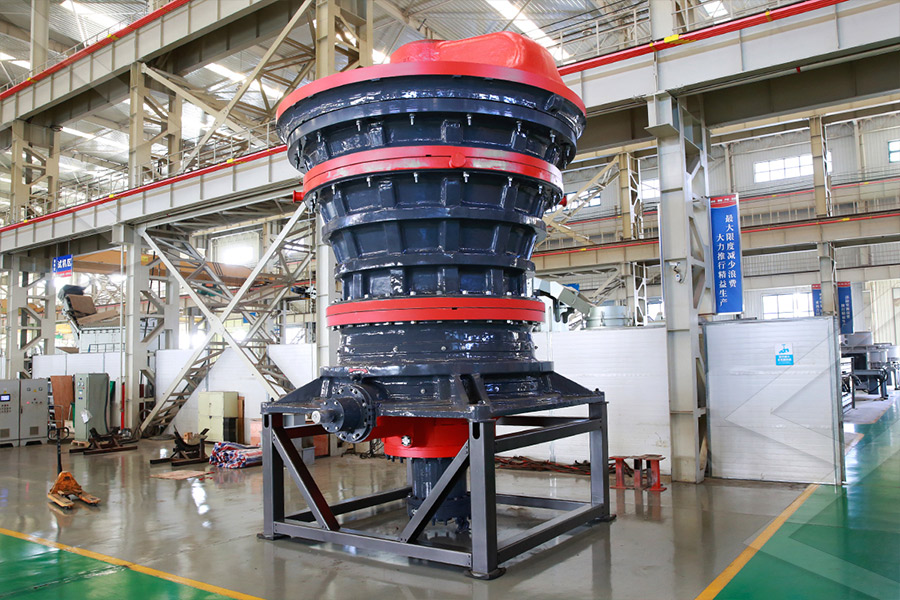

2021年2月18日 Jaw crushers typically use the principles of compression and friction to break materials down They’re extremely powerful equipment that should be used with the utmost care Jaw crushers are so powerful that they’ve earned the moniker “rock breakers” because of their brute force All jaw crushers will have one fixed jaw and a moving one2 天之前 Cone crushers and jaw crushers both work by compression, reducing materials by squeezing them until they break apart The benefit that cone crushers offer over jaw crushers is their ability to output a more cubical product similar to impact crushers Cone crushers have traditionally been used as secondary and sometimes tertiary crushing How Does a Jaw Crusher Work Jaw Crusher Kemper Equipment

Jaw Crusher Primary Crusher in Mining Aggregate JXSC

Product Introduction JXSC jaw type rock crusher is usually used as a primary crusher and secondary crusher to reduce the size of mediumhard materials to smaller physical size Jaw rock crushers are capable of working with the mobile crushing station, underground crushing because of its related small volume Capacity: 11120TPHThe Rebel Crusher Jaw is designed to crush concrete with rebar and wire The Rebel Crusher’s feed system is specifically designed to feed large slabs and chunks of concrete Nobody produces better looking crushed concrete! The REBEL CRUSHER hits the CA DOT spec for crushed concrete in one pass!The Rebel Crusher Crush, Screen and Track RR Equipment

Jaw Crushers Mt Baker Mining and Metals

Complete and ready to run including jaw crusher, belts, motor, fullenclosure guards, all integrated on a steel skid Oversized bearings and castings, robust construction, longwearing cast manganese steel jaw plates Optional steel stand Sizes: 6”x 10” through 20” x 30″ jaw opening Discharge size: ranges from 3/4” minus through 4 2016年2月28日 Large receiving opening per dollar of investment Shape of receiving opening favourable for blocky feed This, plus point 1, give the jaw a definite advantage over the gyratory, except in the very large sizes, for Gyratory VS Jaw Crushers: Advantages

jaw crusher 英中 – Linguee词典

to smaller size chinatrader chinatrader 在JOYAL研磨厂工艺:材料先 进入颚式 破碎 机被粉 碎到 更小 的尺寸。 chinatrader chinatrader The Crusher crushes the powder material to the proper condition [] using units such as 2024年1月19日 Premium ESCO AR 400 and AR 500 wear plate, and Infinity® chromium carbide overlay plate offer a wider choice to address wear protection All liners are made to order Shipment is targeted for 10 Products LSW Wear Parts

(PDF) Influence of jaw crusher parameters on the quality of

2020年3月19日 Aggregate quality is measured in terms of product gradation, particle shape and mechanical properties Feed gradation, crusher setting and crusher speed affects the specific energy consumption 2021年1月30日 Abstract The vibrations of a vibrating jaw crusher model, excited by two selfsynchronizing unbalancedmass vibration exciters, with allowance for the interaction with the processed medium are examined It is found that the frequency range of stable antiphase synchronization of the exciter rotation required for normal operation of the SelfSynchronization of a Vibrating Jaw Crusher with

Jaw Crushers Retsch @dkshgroup

2024年1月19日 Retsch Jaw Crushers are used for the rapid, powerful crushing and precrushing of mediumhard, hard, brittle and tough materials The variety of materials offered, their efficiency and safety make them ideal for sample preparation in laboratories and industrial plants Applications Alloys, basalt, cement clinker, ceramics, chamotte, coal, ROLL CRUSHER Experience superior fatigue strength and reliability with Propel's AVJ Series single toggle jaw crusher, offering versatile mounting optionsJaw Crusher Manufacturer Propel Coimbatore, India

Jaw Crushers Astec

3 天之前 Available in a variety of sizes and configurations, the HydraJaw® crusher, Pioneer® jaw crusher and Iron Giant jaw crushers deliver highcapacity crushing and reliable performance for increased operational productivity and profitability Our diverse line of industryleading jaw crushers offers producers the latest in jaw crushing technology 2023年2月15日 A gyratory crusher is a type of crusher that uses a mantle to guide the crushing process The mantle is suspended on an eccentrically rotating shaft, which causes the mantle to gyrate The gyratory crusher has a higher capacity than a jaw crusher It is often used for primary crushing in the stone crushing industryA Guide to Types of Jaw Crushers for Crushing Rocks and

Pioneer® Jaw Crushers Astec

2024年1月20日 The Pioneer ® Series of jaw crushers represents the very latest in jaw crusher technology Engineered to be the highestcapacity jaw crusher on the market, the Pioneer ® Jaw Crusher will deliver up to 25 percent more tons per hour than comparable jaw crushers Pair that with heavyduty flywheels for reduced horsepower requirements and 2023年6月23日 A Jaw Crusher is sized so that the maximum feed size is 80% of the gape and width openings The gape is the measurement between the two jaw dies, while the width is the measurement between the two side plates For example, if the maximum feed size is 29”x49”, the crusher gape would be 32” and the width would be 54”McLanahan How To Size A Jaw Crusher

Jaw crushr operate manual: how to install, repair and

2022年9月30日 Installation points of the movable jaw Assemble the movable jaw parts in advance After assembling the movable jaw, movable jaw shaft, movable jaw plate, toggle pad, etc on the ground, use a crane or crane to hoist the assembled parts together on the crusher In the rack For sliding bearings, it is necessary to grind and match between the 2023年2月16日 Problem 1: Broken toggle plate A broken toggle plate is a serious problem that requires immediate attention The first step is to shut down the jaw crusher and ensure that all power sources are Problems with Toggle Plates in Jaw Crushers and

Jaw Crusher Jaw Crusher Mannufacturers AGICO Cement

Jaw crusher is suitable for crushing all kinds of ores and rocks whose compressive strength limit is less than 250 mpa It is mainly used as the primary crusher or secondary crusher in cement plant and concrete industries The jaw crusher is divided into three types according to the width of the feeding port: large type, medium type, and small type2023年7月13日 Moreover, with this chamber, the CSS (C in below photo) is measured slightly differently, which also helps in making finer grading with the same CSS compared to other jaws Of course, the flagship jaw dies from utilize MX technology, part of our Max Series Crusher Wears offering The MX jaw is a hybrid product, in which the Are you crushing it with the right chamber for your C

Jaw Crusher for Hard Materials DASWELL

2023年11月16日 Advantages of Daswell jaw crushe 1 The structure is simple and firm, and the production is efficient Daswell jaw stone crusher has a relatively firm frame and can work under high pressure The weight of the equipment is about 15% heavier than other manufacturers, and the structure is stronger and more impactresistant2018年9月15日 7 WHAT IS WEAR? Wear is produced by 2 elements pressing against each other EG Between a jaw liner and crushing material During this process small materials from each element become detached R Crusher Wear Parts Reference Guide

Mobile crushers and screens SRP

Mobile crushers and Screens We offer a wide range of mobile crushers and screens, both tracked and wheeled, to help you process rock in the toughest conditions This selection includes jaw crushers, impactors, cone crushers, screens and scalpers for quarrying, construction and rock excavation projects2 天之前 Applications jaw crushers are designed to exceed the primary crushing needs of customers in the mining, quarrying, and recycling industries These crushers are amongst the most advanced and reliable in the market and are highly productive in a variety of applications Jaw crushers are typically used as primary Jaw Crushers

McLanahan Universal Jaw Crushers

1:59 McLanahan Universal Jaw Crushers are overhead eccentric jaw crushers that continuously reduce material as it passes through the crushing chamber with its aggressive force feed action as the movable jaw compresses inward and downward The sharp primary blow at the top of the chamber reduces material instantly, while a secondary crushing 2018年10月15日 10 One or twopiece jaws Large C Series™ jaw crushers (C110™ and bigger) were originally designed for use with a twopiece jaw die, while the smaller jaw ® C Series™ jaw parts

Jaw Crushers – MEKA

Jaw crushers reduce large rocks or ore by means of compression Mechanical pressure is applied using the crusher’s two jaws; one is fixed while the other makes an eccentric movement There are also primary Rose and English [9] determined the capacity of a jaw crusher by considering the time taken and the distance travelled by the particles between the two plates after being subjected to repeat crushing forces between the jaws Therefore, dry particles wedged between level A and level B (Figure 44) would leave the crusher at the next reverse movement of the jawJaw Crusher an overview ScienceDirect Topics

What Are Jaw Crushers and How Do They Work? Oreflow

2019年3月28日 In a doubletoggle jaw crusher, the moving crusher jaw is driven by the eccentric shaft that moves the front and rear toggles up and down Each shaft revolution causes the moving crusher jaw to close at the downstroke and open up during the upstroke The toggle is kept in place by springloaded tension rod2022年9月20日 This study reports on the design optimisation of the swinging jaw crusher plate Jaw crusher machines are used in the mining and construction industry for crushing rocks and mineral ores to the appropriate sizes for direct application or further processing During the crushing process, large and nonevenly distributed impact forces occur, Optimisation of the swinging jaw design for a single toggle

Jaw Crusher Heavy Duty Jaw Crusher Latest Price,

Roljack Asia Limited Contact Supplier Delhi Scientific Mild Steel Jaw Stone Crusher Manufacturer, Capacity: 300 KG To 500 Ton Per Hour ₹ 50,000 Delhi Scientific Contact Supplier Mild Steel 48"x36" (1200x950mm) Primary Jaw Crusher ₹ 65 Lakh Deepa Machinery Manufacturers Private Limited2020年2月14日 Jaw crusher mempunyai keunggulan struktur sederhana, kinerja stabil, perawatan mudah, menghasilkan partikel akhir dan rasio penghancuran tinggi Jadi jaw crusher merupakan salah satu mesin penghancuran paling penting dalam lini produksi penghancuran batu Secara umum mesin Crusher dapat digunakan untuk mengurangi JAW CRUSHER LinkedIn Indonesia

The Ultimate Guide to Replacing Toggle Plates in Jaw

2023年2月17日 Here are some best practices for maintaining toggle plates: Monitor the condition of the plates: Regularly inspect the toggle plates for signs of wear and tear, and replace them as needed Keep the jaw crusher clean: Clean the jaw crusher regularly to prevent dirt and debris from accumulating on the toggle platesA crusher is a machine designed to reduce the size of large rocks to smaller rocks , gravel , sand, or rock dust; this is essential for efficient transport of the product via conveyors etc Crushing is the first of many stages that lead to separation of the mineral (s) from the waste ( gangue) material Waste material can be discarded or Jaw Crusher Explained saVRee

Jaw Crushers high quality and reliability from RETSCH

Retsch Products Milling Jaw Crushers The RETSCH Jaw Crusher range is used for the rapid, powerful crushing and precrushing of mediumhard, hard, brittle and tough materials The variety of materials offered, their efficiency and safety make them ideal for sample preparation in laboratories and industrial plants Benchtop Unit